Introduction to Calibration Services

Calibration services are essential for maintaining the accuracy and reliability of measurement instruments and equipment across various industries. These services involve the comparison of the readings of a device or instrument to known standards to determine its accuracy and make necessary adjustments. In this comprehensive guide, we will delve into the world of calibration services, exploring their importance, types, and benefits.

Understanding Calibration Services

Calibration services play a crucial role in ensuring the accuracy and reliability of measurement instruments used in fields such as manufacturing, healthcare, aerospace, and automotive industries. By periodically calibrating instruments against traceable standards, calibration services help businesses maintain quality, consistency, and compliance with regulatory requirements.

Types of Calibration Services

Calibration services can be classified into several types based on the instruments being calibrated and the calibration methods used:

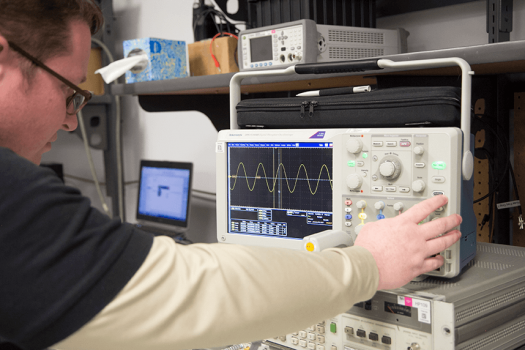

- Electrical Calibration: Calibration of electrical instruments such as multimeters, oscilloscopes, and power supplies to ensure accurate voltage, current, and resistance measurements.

- Mechanical Calibration: Calibration of mechanical instruments such as torque wrenches, pressure gauges, and weighing scales to ensure accurate force, pressure, and weight measurements.

- Dimensional Calibration: Calibration of dimensional instruments such as calipers, micrometers, and gauges to ensure accurate length, width, and height measurements.

- Temperature Calibration: Calibration of temperature instruments such as thermometers, thermocouples, and thermal cameras to ensure accurate temperature measurements.

- Flow Calibration: Calibration of flow instruments such as flow meters, rotameters, and mass flow controllers to ensure accurate flow rate measurements.

Importance of Calibration Services

Calibration services offer several benefits to businesses and industries:

1. Ensuring Accuracy

By calibrating instruments against known standards, calibration services ensure the accuracy and reliability of measurement readings, reducing the risk of errors and inaccuracies in processes and products.

2. Meeting Regulatory Requirements

Many industries are subject to regulatory requirements that mandate the calibration of measurement instruments. Compliance with these regulations is crucial for maintaining product quality, safety, and regulatory compliance.

3. Improving Product Quality

Calibration services help businesses produce high-quality products by ensuring that measurement instruments provide accurate and consistent results, leading to improved product performance and customer satisfaction.

Benefits of Outsourcing Calibration Services

Outsourcing calibration services to third-party calibration laboratories offers additional benefits:

1. Expertise and Experience

Calibration laboratories have specialized expertise and experience in calibrating a wide range of instruments, ensuring accurate and reliable results.

2. Traceability and Documentation

Calibration laboratories provide traceable calibration certificates and documentation, demonstrating compliance with regulatory requirements and quality standards.

3. Cost Savings

Outsourcing calibration services can result in cost savings compared to in-house calibration, as businesses avoid the need to invest in expensive calibration equipment and training.

FAQs

What is the purpose of calibration services?

Calibration services are essential for ensuring precision and accuracy in measurements by comparing the readings of instruments or devices to known standards. The primary goal is to verify and adjust equipment to maintain reliable and accurate measurements, critical for quality assurance and compliance with regulatory standards.

How does calibration contribute to precision and accuracy?

Calibration ensures precision and accuracy by identifying and correcting any deviations or inaccuracies in the measurements of instruments or devices. Through comparison with known standards and adjustment as necessary, calibration helps maintain consistent and reliable measurement results, reducing errors and uncertainties.

What industries benefit from calibration services?

Various industries rely on calibration services to maintain the accuracy of their equipment and ensure the quality of their products or services. This includes manufacturing, pharmaceuticals, healthcare, aerospace, automotive, electronics, research and development, and many others where precise measurements are crucial for success and safety.

What are the consequences of not calibrating equipment regularly?

Failure to calibrate equipment regularly can lead to inaccurate measurements, compromising product quality, safety, and regulatory compliance. It may result in costly errors, product recalls, legal liabilities, and damage to reputation. Regular calibration helps prevent such consequences by ensuring that equipment operates within acceptable tolerances.

How can businesses implement effective calibration programs?

Implementing an effective calibration program involves several key steps, including selecting qualified calibration service providers, establishing calibration schedules based on industry standards and equipment requirements, maintaining accurate documentation, training personnel, and continuously monitoring and improving calibration processes to ensure precision and accuracy.

Conclusion

Calibration services are essential for ensuring the accuracy, reliability, and compliance of measurement instruments across various industries. By mastering the principles and practices of calibration services and leveraging the expertise of third-party calibration laboratories, businesses can achieve precision and accuracy in their measurements, leading to improved product quality and customer satisfaction.